Approaching the loading zones in factories; Truck, Truck, Trailer etc. All equipment used to safely load vehicles from loading points are called factory vehicle loading systems. Many products are used in the factory loading areas under this subject. Our company continues its R&D-based productions in order to make Karen system loadings safer and to prevent and prevent accidents with loss of material and life.

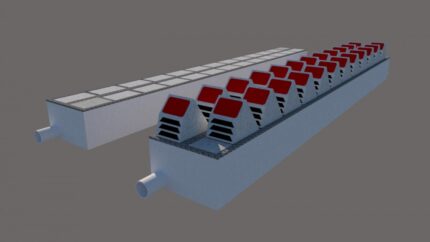

At the factory sites, the loading areas are separated from each other by steel wheel separators. Each vehicle approaches back to the front of the door to be loaded . At this point the wheel lockers and some sensors work . When the semi-trailer or trailer part reaches the front of the loading ramp, the sensors detect the vehicle. If the vehicle approaches the loading point more than the allowable limit line, the reverse wheel arrester will operate. Stop the vehicle so that it does not crash into the loading ramp. Recklessly, the vehicle that is approaching backwards and crosses the red tolerance line, catches the wheel and stops it. It does not damage the vehicle. It prevents the vehicle from hitting the loading point and causing material damage.

The vehicle has now safely approached the appropriate loading limit . Automatically, the security locks are activated with the first start. This time, the working wheel locks are the wheel locks that work in the opposite direction of the wheel lock, which prevents the vehicle from crossing the border when approaching backwards. This lock prevents the loading forklift from falling between the dock and the vehicle by sliding forward during vehicle loading. The tires of the vehicle are locked with the tire wheel holder locks and the vehicle is fixed. There are many different versions of wheel holder locks. All of these versions are in our product portfolio as our company Karen system production. You can choose one of the most suitable safe wheel locking systems from the product descriptions below.

Safe loading automation systems logic with PLC and software; There is a possibility that the driver of the vehicle to be loaded will compress people while approaching the dock, due to long-distance fatigue and blind spot areas of large vehicles. Unfortunately, fatal accidents may occur in the face of this undesirable situation. Our new occupational safety legal systems work as follows . In order to prevent these accidents, the loading dock area is equipped with special sensors. The area that the driver cannot see is the rear bumper of the truck. While the truck is approaching backwards, jamming between the loading ramp and the rear bumper of the truck and fatal accidents occur in this area. Our sensor part that prevents this is buried in the ground in front of the dock. If there is a person in this area, the sensor embedded directly on the ground detects the truck and the information coming from the two sensors is processed, since the truck approaches backwards. Logical work comes into play. The truck is coming back , The risk has passed the area , There is a person in the risk area , Immediately remove the reverse wheel lock and stop the truck . If there is no person in the risk area , the truck will approach normally . In order to open the tailgate, the wheels must first be locked. If the wheel is locked, the sensor here informs the door. I’m locked, now the loading door can be opened. Installation is done securely. In order to unlock the wheels after the loading is finished, the loading door must be closed first, otherwise the wheel locks will not be unlocked. The loading door is closed . The closed information goes to the wheel lock. And the wheel is unlocked. The vehicle leaves the loading dock .

We have many products used in loading systems.

1. Hydraulic and electromechanical loading ramps

2. Industrial garage doors

3. Loading point bellows systems

4. Additional equipment to cut off the air circulation between the vehicle and the loading area

5. Vehicle tire and wheel lock holders

6. Steel separators to separate the loading zones

7. Automatic loading systems for trucks, lorries and trailers

8. Making loading points safer with automation systems, PLC and software