Road Blocker

What is Road Blocker Barrier?

Road blocker barriers are high security barrier systems that are generally used to control or limit the passage of vehicles. These barriers are especially used in places where high security is required such as military facilities, large shopping malls, airports, ports and similar places. Road blocker barriers are designed to prevent or prevent vehicles from passing at high speed.

They have a durable structure, usually made of concrete or steel blocks, and are high enough to prevent vehicles from passing over them. Also, by working with a control unit, vehicles can be kept in front of the barrier or allowed to pass. These barriers are an effective security measure used to increase security and especially to protect against terrorist attacks.

Where is Road Blocker Barrier Used?

Road blocker barriers are used to help keep vehicle traffic under control, especially in high security areas. Below are examples of some places where road blocker barriers can be used:

1. Military facilities: Road blocker barriers are used in military bases, warehouses and similar places to allow vehicles to enter and exit in a controlled manner.

2. Airports: Road blocker barriers are used at airports to ensure that vehicles move in limited areas, to prevent uncontrolled entrances and to increase security.

3. Ports: Road blocker barriers are used in ports to enable vehicles to move in limited areas, to increase security and to prevent unauthorized access.

4. Large shopping malls: Road blocker barriers are used in large shopping malls, stadiums and similar places to allow vehicles to enter and exit in a controlled manner.

5. Consulates and diplomatic missions: Since consulates and diplomatic missions are high-security areas, the use of road blocker barriers is also common here.

These are just a few examples, the use of road blocker barriers is necessary wherever vehicle traffic needs to be controlled.

How to Install Road Blocker Barrier Systems?

Road blocker barriers are usually installed by a professional team. The installation process may vary depending on the barrier’s installation location, ground conditions and other factors. But in general, the installation of road blocker barriers includes the following steps:

1. The place of installation is determined: The place where the barrier will be installed is determined and it is prepared appropriately, taking into account the ground characteristics.

2. Excavation is done: The pit or channel required for the lower part of the barrier is excavated. This is important so that the barrier can be installed securely.

3. Foundation is made: Foundation is made on the lower part of the barrier. This foundation ensures that the barrier is firmly fixed to the ground.

4. The barrier is installed: The steel construction of the barrier is installed and other components such as motor, hydraulic or electronic systems are added to the top.

5. Tested: The barrier is tested for correct operation and safe operation.

6. Commissioning: Electronic systems, control panels and other components required for commissioning and controlling the barrier are installed.

The assembly process may vary depending on the barrier’s characteristics, size and intended use. It is therefore important to always follow the barrier’s manufacturer’s instructions during the assembly process.

Road Blocker Barrier Systems Prices , What are the Costs ?

Road blocker barrier systems have a price range that varies according to different sizes, technical features, brands and manufacturers. In addition, installation costs and additional components (eg control panel, sensors, power supply, etc.) can also affect the cost. In general, the average prices for road blocker barrier systems are roughly as follows:

Low-capacity barrier systems (according to company quality): It can vary between 5,000 – 6,000 USD. (We do not recommend these runes in terms of quality. There are no such products in our products, they are given for information purposes.)

Medium-capacity barrier systems (non-approved crash-tested): It can range from $7,000 to $8,000.

High-capacity barrier systems (These are products with approved crash tests in ASTM Standards such as K4, K8, K12, PAS68, and IWA): 8500 – can cost 10,000 USD or more.

These prices are only estimates and the prices of road blocker barrier systems can vary greatly depending on many factors. In addition, additional components to be used and installation costs can also affect the cost. Therefore, it would be best to get a quote from a manufacturer or supplier to calculate the cost for a specific project. We, as Karen system company, are ready to assist you in the most suitable and quality conditions. We have 25 years of work experience in barrier systems.

What Parts Does the Road Blocker Barrier System consist of?

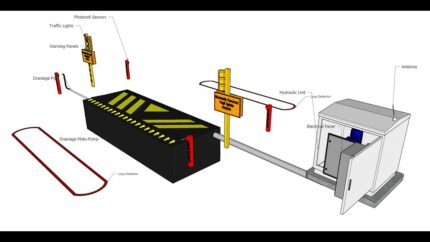

Road blocker, which is an anti-terrorist barrier system, is a system consisting of many different parts. Here we have listed the main components required for a typical road blocker system:

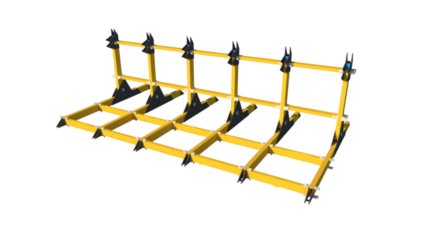

Road Blocker Frame: It is the main body of the barrier and is usually made of durable steel materials.

Hydraulic System: There is a hydraulic system consisting of many components such as hydraulic cylinders, hydraulic pump, hydraulic oil, hydraulic hoses and control valves that move the moving part of the road blocker up and down.

Control Panel: It is the panel with electronic components that control the road blocker barrier. This control panel controls many features such as vehicle transitions, user settings and fault conditions.

Sensors: These are the sensors that detect the movement around the road blocker. The sensors detect the approach and departure of the vehicle and enable the road blocker to be opened and closed.

Power Source: It is a power source that provides the electrical energy required for the operation of the road blocker.

LED Lights: The road blocker is equipped with flashing LED lights to allow vehicle drivers to notice the presence of the barrier.

Lock Systems: In order to increase the safety of the road blocker, there are special lock systems that allow the barrier to be locked.

Road blocker, which is an anti-terrorist barrier system, is a complex system used especially in areas requiring high security. For this reason, the installation and maintenance of road blocker barrier systems should be done by experts.

How Many Meters Is the Road Blocker Barrier System Manufactured?

Road blocker barrier systems can usually be manufactured in lengths that can be customized according to the customer’s needs. As standard, road blocker barrier systems can be produced in lengths ranging from approximately 2-4 meters. However, it is possible to manufacture longer or shorter barrier systems. 5-5.5 – 6 meter barrier systems can be designed and produced especially according to special project needs.

What are the Standards of Road Blocker Barrier Systems?

There are certain standards for road blocker barrier systems. These are usually specified to ensure the safety and durability of the barrier. Common standards for road blocker barrier systems are:

- ASTM F2656-07 Standard Test Method for Vehicle Crash Testing of Perimeter Barriers

- PAS 68 (Publicly Available Specification) for vehicle security barriers

- IWA-14-1:2013 VSB (Vehicle Security Barrier) Performance Standard

- Certain vehicle impact resistance classifications such as K12 or K4 ASTM M50 (ASTM F2656/F2656M-15) and/or PAS 68 (2013)

These standards also include specific test procedures for testing barrier systems and determining their performance. These tests help determine the crash, post-impact safety, impact resistance and other properties of barriers.

The standards applicable to road blocker barrier systems may vary according to countries and areas of use. However, manufacturers often design and manufacture in accordance with the most common safety standards.